KOH YOUNG TECHNOLOGY

Absolute No.1 Inspection Company

- 3D Solder Paste Inspection.

- 3D Automated Optical Inspection.

- 3D Semiconductor Packaging Inspection.

- 3D Dispensing Process Inspection

If you are interested in one of these products please contact a PMR Sales Representative

KY series and aSPIre 3

- Koh Young SPI systems provide precise 3D measurement of solder paste deposits, including volume, height, area, and bridging, ensuring high-quality solder joints.

- Detect various solder paste defects, such as insufficient paste, excess paste, bridging, and shape deformities, enabling early identification and correction of process issues.

- By providing detailed data and analysis, Koh Young SPI systems enable real-time process monitoring and optimization, leading to improved yields and reduced rework.

- Koh Young SPI systems feature intuitive software interfaces and can be integrated with other manufacturing equipment for seamless data sharing and process control.

Please download supporting material:

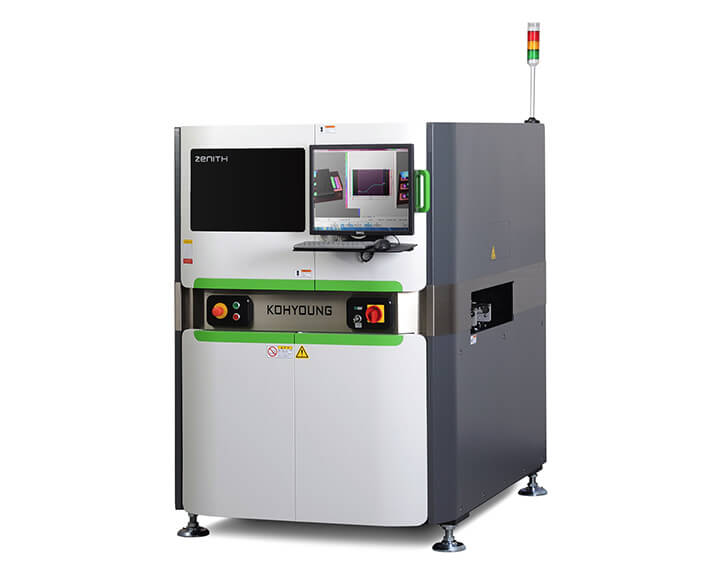

Zenith 3D AOI

With Revolutionary New 3D Measurement.

- detect a wide range of defects on PCBs, including component placement errors, soldering issues (like bridges, opens, and insufficient solder), and other visual imperfections.

- Koh Young AOI systems incorporate 3D measurement capabilities, providing detailed information about component height and other critical parameters for more accurate defect detection.

- Advanced algorithms and image processing techniques help to minimize false calls, reducing the need for manual verification and improving inspection efficiency.

- Koh Young AOI systems provide detailed data and analysis tools, allowing manufacturers to identify trends, optimize their processes, and improve overall product quality.

- KPO Link provides seamless connectivity and data exchange between Koh Young's SPI and AOI systems, enabling closed-loop feedback for process optimization. This integration allows manufacturers to leverage data from both inspection stages to identify and correct process variations earlier, minimizing defects and improving overall production efficiency.

Please download supporting material:

Neptune DPI

With Revolutionary New 3D Measurement.

- Neptune systems provide accurate 3D measurement of dispensed materials (like solder paste, adhesives, and sealants) and coatings, ensuring consistent and controlled application.

- Detect a wide range of defects, including insufficient material, excess material, voids, and shape deformities, enabling early identification and correction of dispensing/coating issues.

- Neptune systems use non-destructive optical measurement techniques, allowing for inspection without damaging the product.

- The systems can be integrated into automated production lines, enabling real-time process monitoring and adjustment for improved efficiency and quality.

- The Neptune product line caters to various applications, including printed circuit board assembly, semiconductor packaging, and other microelectronics manufacturing processes.

Please download supporting material:

Support

USA.(470) 374-9254 kya_support@kohyoung.com